Blog # 229 I talked about Meanwhile back in Las Vegas then off again. In this blog I want to talk about 2005 comes to an end and another China trip.

So 2005 was a crazy year for me. I ended a 20 year marriage and traveled all over the world extensively. I went to Italy, Germany, and China. Plus throw in 4 Ffany trips to NYC and 2 Vegas shows as well. I did get to take my son James to China which was a good experience for him to see other countries and cultures.

Zappos was recognized by Inc. 500 magazine as the 23rd fastest growing private companies. There was a nice write up about our company and crazy culture which was cool to see in print. On top of that, Footwear news awarded Zappos the E-Tailer of the year award while we were all in NYC for Ffany. We recorded another record day while we were there by breaking 2 million dollars in a single day. We did the usually Irish Pub celebration with countless beers and shots and regretted it all the next day at Fred’s 7am breakfast meeting. “You have to answer the bell” Fred would say, which is tattooed in my mind forever. Good times though.

January and the new year comes around and we left for China on the 4th. Tommy was going with us this time to help develop our men’s business. He had an amazing flair for fashion and I was excited to bring him with us. He is Jon’s brother and just a great guy. I really enjoyed him being on the team and adding a men’s fashion take for us.

While I was in the Fashion area, we used to buy the brands Men’s & Women’s with one sales plan. I suggested we break it out by gender to see if it would increase business. My thought was, if you focus on Men’s separately instead of mixed in with Women’s you would have better results.

I thought the people with Men’s background would support this idea, but they thought I was crazy. “We are a women’s site primarily “I would hear. I did it anyways and our Men’s business had 50-60% increases that year.

I wanted to continue this thought process for our private label area as well. We went to several factories that specialized in men’s product and Tommy’s eye was definitely helpful. With the minimum quantities we had to write, we wanted to make sure we had winners. It was easy to do the safe styles but to add some style you had to know your stuff. We were going to develop Men’s in three brands, Type Z, RSVP and Fitzwell. An edgy brand with Type Z, mainstream with RSVP and comfort with Fitzwell.

We checked out the box factory too as they had our new box samples that Jon created the designs for. They looked amazing. Especially the Type Z box which had a metal ring on the side too to give that edgy feel. Now we had quality product, better boxes and tissue to coordinate. Our next step was to add shoe bags that would come in the boxes with every pair. We started the conversations with Rob, and we will revisit in our next trip out.

Tommy was leaving a little earlier than Richard and I, so it gave us an opportunity to check out a few new factories close to the hotel. Richard talked to someone during breakfast about a wood bottom factory close by. I wanted to find some cool wood bottoms for our Gabriella Rocha brand.

We get to the factory and basically from the outside it looked like a common garage that a lot of merchants use as store fronts. We go inside and they take us downstairs to this huge room. For some reason it reminded me of a scene in a scary movie. I was a little nervous as it seemed kinda sketchy.

It was super hot down there with poor ventilation. They had huge logs stacked up that they were cutting with chainsaws. Wood chips were flying all over the place and everyone was in tank tops and sweaty. It was neat to see on one hand but there were several violations going on here from a health code perspective. There were a lot of really young people there too which was in question.

We go down yet another floor and people were gluing things and spraying the sealer on the wood bottoms. The ventilation was horrible, and I wondered how people did this all day. I was getting a major headache from the fumes just being there for a few minutes let alone working an 8–10-hour day. We knew right away we weren’t going to use this facility, but it was a good experience to see this side of the shoe business. It gave a new meaning to the phrase “Sweat shops.”

…just sharing my story and tips from my footwear career.

Subscribe to my Blog by filling out the info below and then press the “subscribe” button

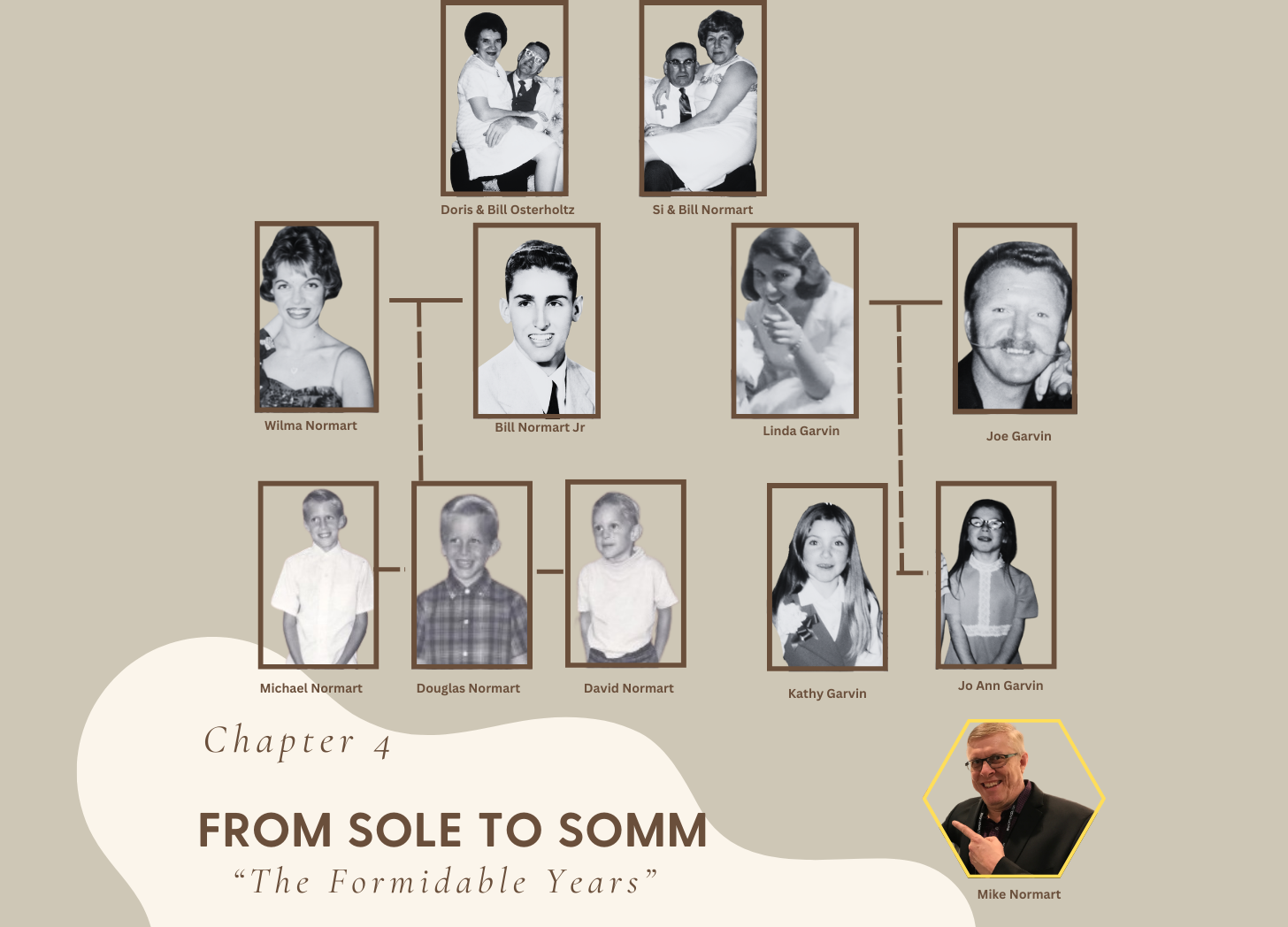

From Sole to Somm – My Brothers and 1st Cousins

From Sole to Somm – The Impressionable Years