Blog # 208 I talked about Day one we visit a tannery. In this blog I want to talk about next up we tour a last factory.

We arrived at the last factory and met the manager of the facility. She was super excited about showing us around. The process starts with a large resin form but even before that a sample last must be made. They take an original sample shoe and insert epoxy at the front, ball, and heel to create an accurate shape. Then by hand they file and add material if needed to get the perfect shape.

The prototype is taken to a digital machine and is scanned by the computer for the shape and measurements (Similar to a key making machine). Once the digital machine gets the measurements, plastic molds are created by injecting blue powder imported from Taiwan into the molds. Basic lasts are created.

Lasts are placed on another computerize machine to record the shape and measurements into the system. Size runs are created all at one time through the computer and digital information. There is a last for each size and width.

A cutting machine creates the last based on the specs and is very quick. There were these mechanized arms that circled the last like something from a futuristic movie. It would cut pieces little by little but very quickly. I think we were all in awe of this part of the process. Blue fragments were flying around the inside of the machine. All lasts are finalized by adding a metal piece at the heel and ball of the feet.

Lasts are finished and measured by hand and are then filed or sanded and fine-tuned. Every last is cataloged and numbered so for future use the number just has to be inputted. There were huge bins full of lasts as a “library of lasts”.

…just sharing my story and tips from my footwear career.

Subscribe to my Blog by filling out the info below and then press the “subscribe” button

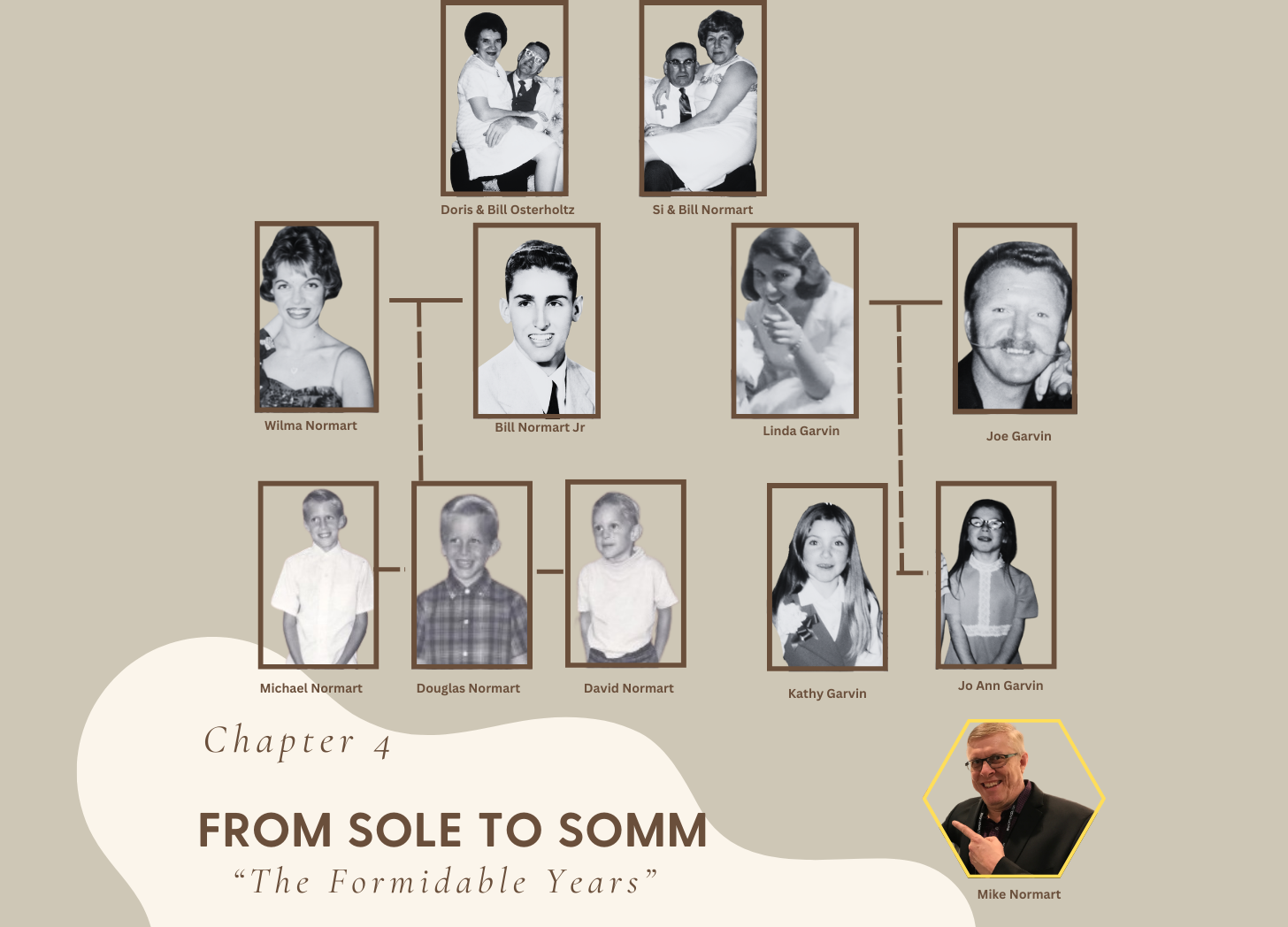

From Sole to Somm – My Brothers and 1st Cousins

From Sole to Somm – The Impressionable Years