Blog # 211 I talked about Next the shoe line tour. In this blog I want to talk about how the Gel for Fitzwell idea is born

Bottom Factory

First stop was a molded bottom factory. It was smaller than the shoe factories as they specialized in just making the molded bottoms. There were cast iron forms which were quite large and heavy as well. They were all on a circular machine that would stop at each different station. The liquid material they used would be squirted into the mold to fill it up in station one. The whole line would rotate and the next mold would be filled up. The next station would press the mold and the material would activate. By the time it finished the next few steps to correctly make the bottom, the last station would pull the bottom out and clean the mold for the next round. It was extremely hot in this factory

Gel Factory

Next up was a gel factory. They made insoles for Dr Scholls. We saw them making gel insoles and Fred asked me “why don’t we add gel insoles to Fitzwell?” We all looked at each other at the same time like he discovered something. It was a great idea, but we had to have our own spin on it for trademark reasons. We asked them if there was a generic Gel pod we could use. There was a front pod and a heel cup pod that I liked. The thought I had after Fred’s suggestion, was to incorporate this in all shoes, dress or casual. We needed to have a cool aesthetic that was attractive but functional.

They were going to make up some mock-ups for us and we would revisit on the next trip. When we got back everyone’s creative juices started flowing. Tony thought we should do the gel pods in the shape of a heart. Fred liked the idea as well. . I thought it might infringe on a brand called Blue Heart at the time so decided to stick with the two-pod system we were offered.

I was really excited about this because I felt this would take Fitzwell into a whole different direction. The styles we currently had were not that exciting and kinda ugly. They were basic comfort shoes. My vision for the brand would be to modernize the styling and create a great shoe for the office or for retail workers that are on their feet all day. Now that we had the concept for the brand figured out, we needed to find factories that could incorporate it into the product.

Box Factory

The last stop for the day would be to a box factory. Our current boxes were basically white boxes that we put a sticker on. It looked really cheap. If we were going to produce a high-quality product then we needed the boxes to portray that too. This factory was really interesting, and they were willing to work with us.

They took us through the whole process. It started with the design itself. It went from the computer to a machine that would have the colors inputted and put to the stock cardboard they would use. From there The cardboard stock went through a conveyor belt that had flames shoot up to dry the cardboard as it passed through. Finally, it landed at the cutting machine that cut it to the specs inputted. For our part we needed to work on our designs. I planned to see if our team back home could help me with this.

With all the different places we were seeing we felt it was best to be more centrally located. We settled on the Haiyatt garden hotel in Houjiie. We all chuckled a bit at the names of some of the hotels in China as they were close in name to other famous hotels back home with an added letter here and there. Little did I know this would be my home away from home for the next 4 years, as I was travelling to China every 6 weeks now.

Our business was growing quite rapidly with some of the small changes we made already to be at 4% of the company’s volume. It would be exciting to see what we could do once some of these new ideas would be put into place.

…just sharing my story and tips from my footwear career.

Subscribe to my Blog by filling out the info below and then press the “subscribe” button

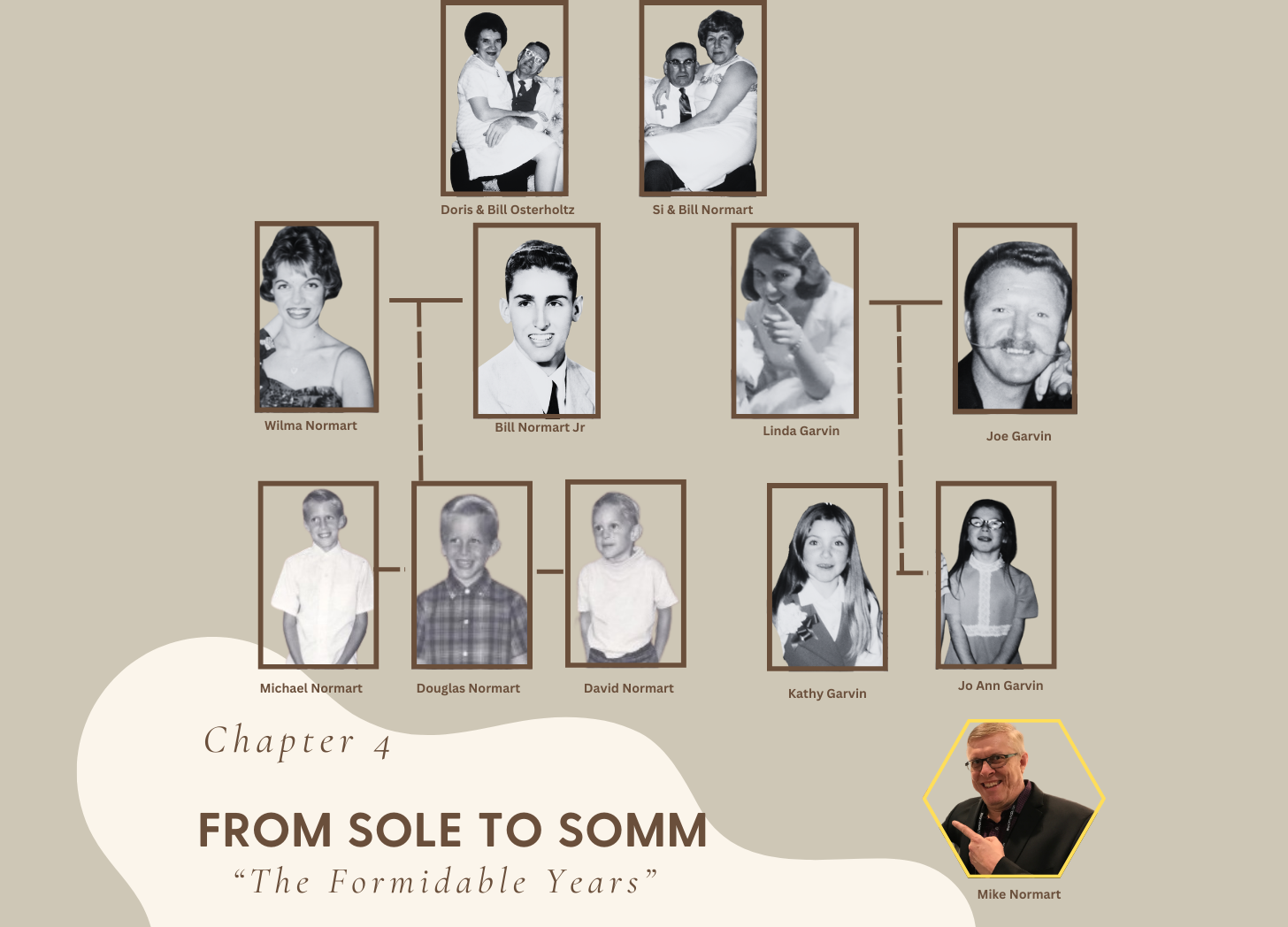

From Sole to Somm – My Brothers and 1st Cousins

From Sole to Somm – The Impressionable Years