Blog # 222 I talked about Anna starts and back to China. In this blog I want to talk about Our first Quality Control tour.

We were learning more and more about the world of private label every day. One thing we wanted to check into was getting our own Quality Control company that would make sure we were getting quality product. Today was a tour to a company that provided that service. Most companies had some sort of QC as they called it in the factories. Some were better than others and some where none existent. With some of the restrictions that the states have in this area we wanted to make sure we were covered.

But first we had to get through the China traffic as it was a ways a way. Driving in China was always an adventure. People drive on the wrong side of the road , and talk about gridlock. In the states you can see an aerial view of traffic and pretty much see straight lines of traffic. In China it goes every which a way. It’s a mess. So when you get stuck in traffic it’s a nightmare.

Cora and team were there to great us as we arrived. They were great, they explained every machine with detail and what the purpose was for each test. There were dozens of testing machines, and each had a specific purpose. We went to every station and I must say it was pretty thorough

There were tests for heat tolerance to see if the glue would hold up. Basically, putting the product in a high heat oven. There was a heel test in which a device would rise in the air and then come down hard on the heel to see if the leather would nick. Another test flexed a shoe a few hundred times to see if the sole would crack. It reminded me of a torture chamber for shoes.

After we were done we went into an office and negotiated a price per shoe for testing. We would have to factor that cost into the price so we wanted to go back and crunch some numbers before we committed. They were good people in this facility so we left very impressed by their operation.

…just sharing my story and tips from my footwear career.

Subscribe to my Blog by filling out the info below and then press the “subscribe” button

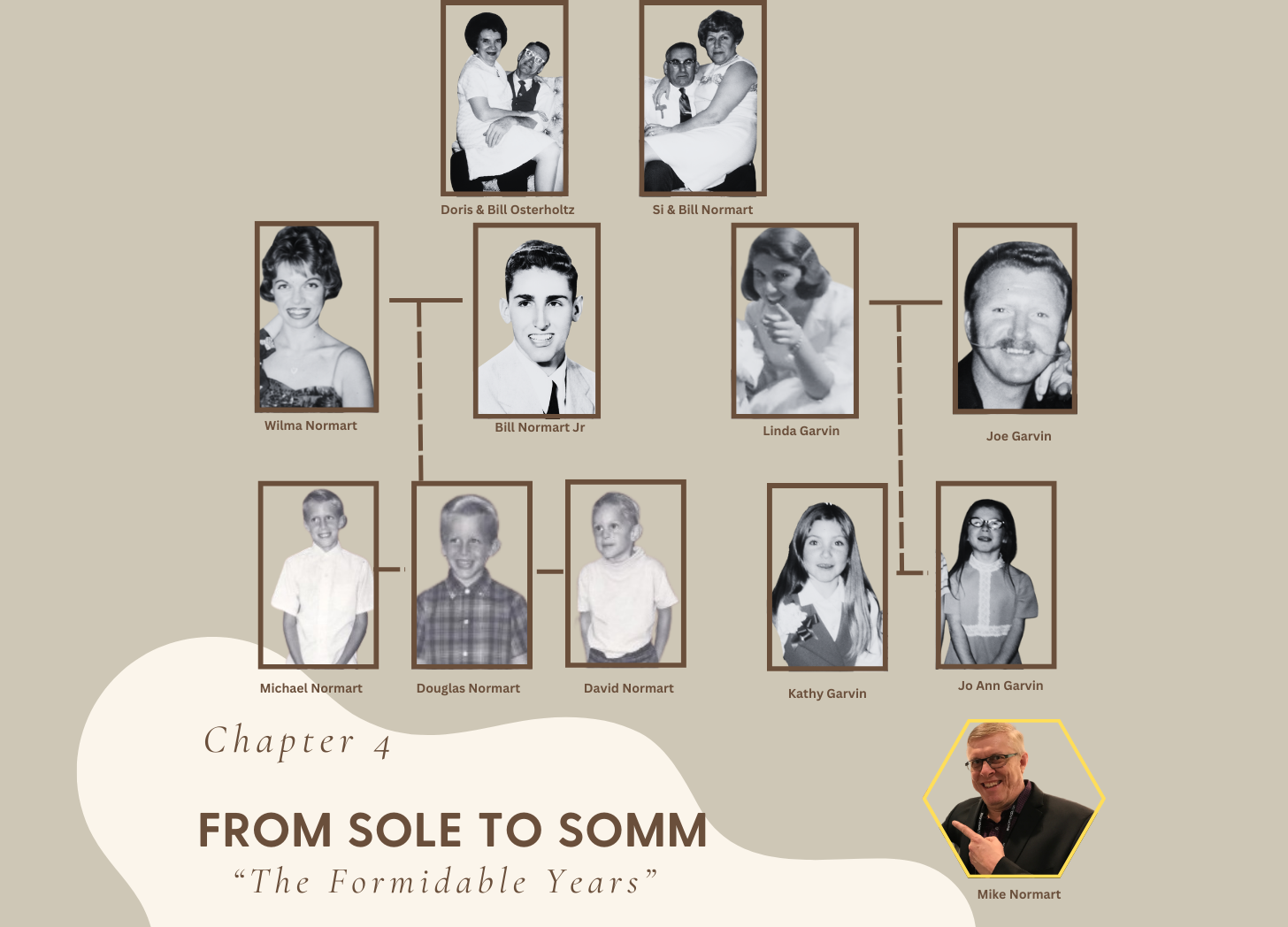

From Sole to Somm – My Brothers and 1st Cousins

From Sole to Somm – The Impressionable Years