Blog # 210 I talked about today we tour several shoe factories. In this blog I want to talk about Next the shoe line tour

The stitching room sews all the components together to be sent to the line where they actually put the shoe together.

In China each factory has about 10 lines so they can make different styles at the same time or just more of one style. Hundreds of people work these lines. Each person has a station and does the same thing all day long. For the glue stations there are huge vents over head to handle the fumes. You could still smell the fumes, but they weren’t as strong. I couldn’t imagine having to smell that all day long.

Uppers are constructed together with the mid-sole. This is also called a “board”. It is either nailed or taped in place. The upper is usually nailed to the last with a “lasting tack”. It is attached to a sole with a machine and sent further down the line. Next phase is to heat the shoe. The shoes travel down the line and pass through an oven.

The heating process removes all moisture from the shoe and allowed the shoes to be formed by hammering. The cooling process finalizes the shoes around the last. So basically, they go through an oven then it gets cooled down. Another machine takes the last out as a final process. If you have ever experienced a nail in the insole it’s because someone wasn’t paying attention in this last step.

The shoes are then inspected and are given the final touches on each shoe to pass QC (Quality Control). Shoes needs to be perfect to be able to ship. Remove any shoes that do not meet appropriate quality.

Rob became retail Rob in the process. He was so excited he started talking fast again. It was a beautiful thing to see. He took us to several factories and was very well respected by the factory people.

The hotel we were staying at was really nice but far away from everything. Richard asked Rob if there was a hotel closer or more centrally located. The Haiyatt was a hotel a lot of the shoe people stayed at or the Sheraton. We would find out tomorrow if we were moving.

We had a nice dinner that night and were going to see A gel factory and a molded bottom factory for tomorrow. We also were going to check out a box factory to see if we could make our own boxes. Everything was starting to come into place here so I was pretty satisfied with the results we were getting from this trip.

…just sharing my story and tips from my footwear career.

Subscribe to my Blog by filling out the info below and then press the “subscribe” button

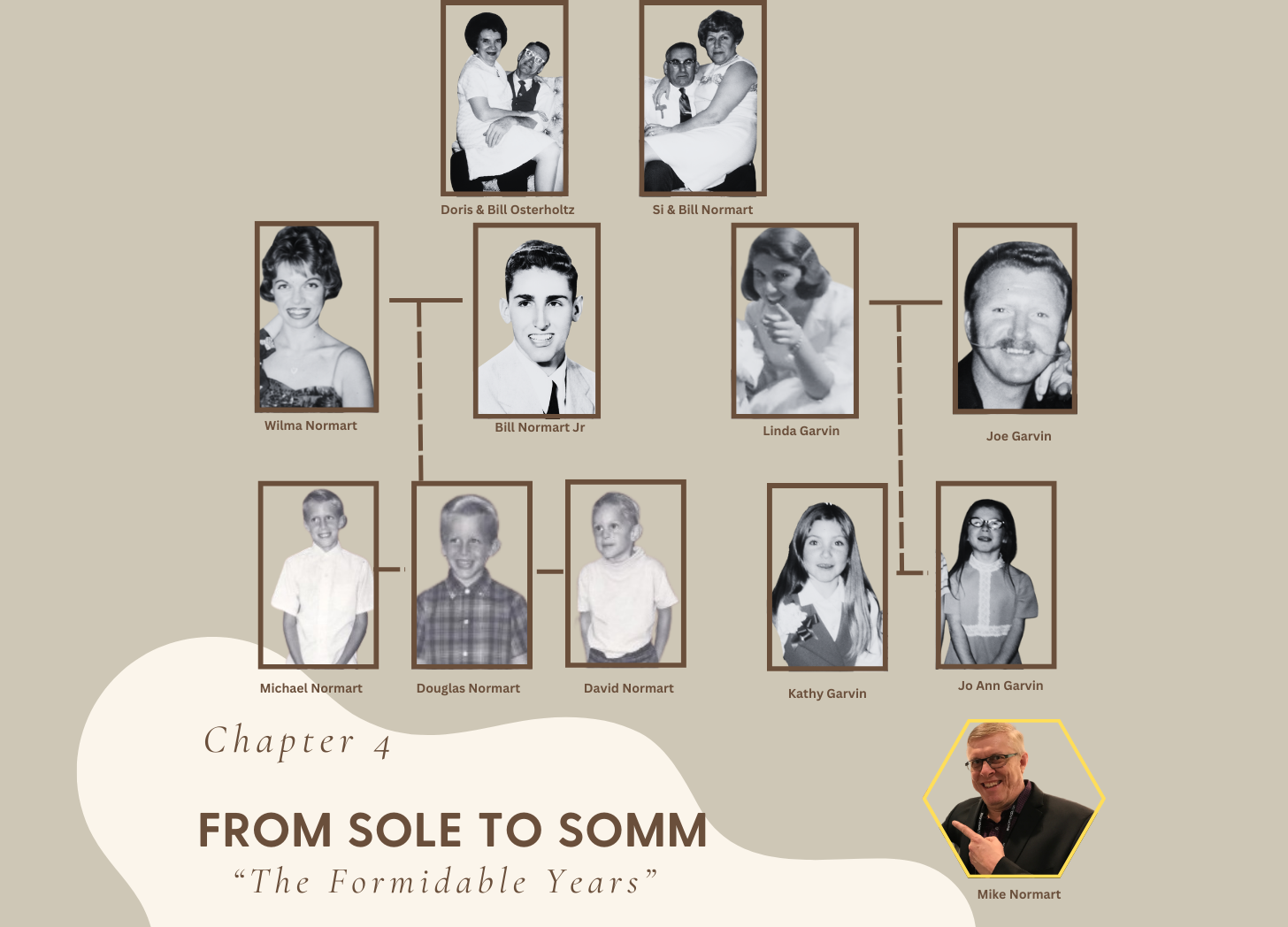

From Sole to Somm – My Brothers and 1st Cousins

From Sole to Somm – The Impressionable Years